- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

Hot Sale Automatic 3 / 5 Gallon Brushing Washing Machine Gallon Water Production Line

Barrels under the convey system enter into external washing machine, and tightly close to main circle soft brush. Main circle brush travel direction reverse to barrel rotary direction. Barrel under the function of the thumb wheel finish revolution once, rotation forth. Washing pump go on spraying water and cleaning lotion to each brush and collect water for circle return usage. Outside barrel washing is under 270°, after revolution then enter into showing washing then convey out. The spray water and washing lotion of Showing room coming from the same pump, also for return and circle usage.

| Model | QGF-80 | QGF-150 | QGF-300 | QGF-450 | QGF-600 | QGF-900 |

| Filling heads | 1 | 1 | 2 | 3 | 4 | 6 |

| Filling volume | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 |

| Barrel size | φ270×490 | φ270×490 | φ270×490 | φ270×490 | φ270×490 | φ270×490 |

Production capacity (BPH) | 80 | 150 | 300 | 450 | 600 | 900 |

| Gas pressure(KPA) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 1 | 1.2 |

| Gas consumption | 0.37 | 0.37 | 0.6 | 0.8 | 1 | 1.2 |

| Motor power(KW) | 1.38 | 1.75 | 3.8 | 3.8 | 7.5 | 9 |

| Motor voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Weight(KG) | 500 | 700 | 1200 | 1600 | 2000 | 3500 |

Overall dimension(MM) | 2500×1100×1600 | 2800×1100×1600 | 3800×1300×1600 | 4200×1600×1600 | 4800×800×1600 | 4200×2300×160 |

3 / 5 Gallon Bottle Filling Machine

1. About auto loading device

The chain board on conveyor is made with stainless steel. The appearance of foot stand is perfect, and the height can be adjusted.

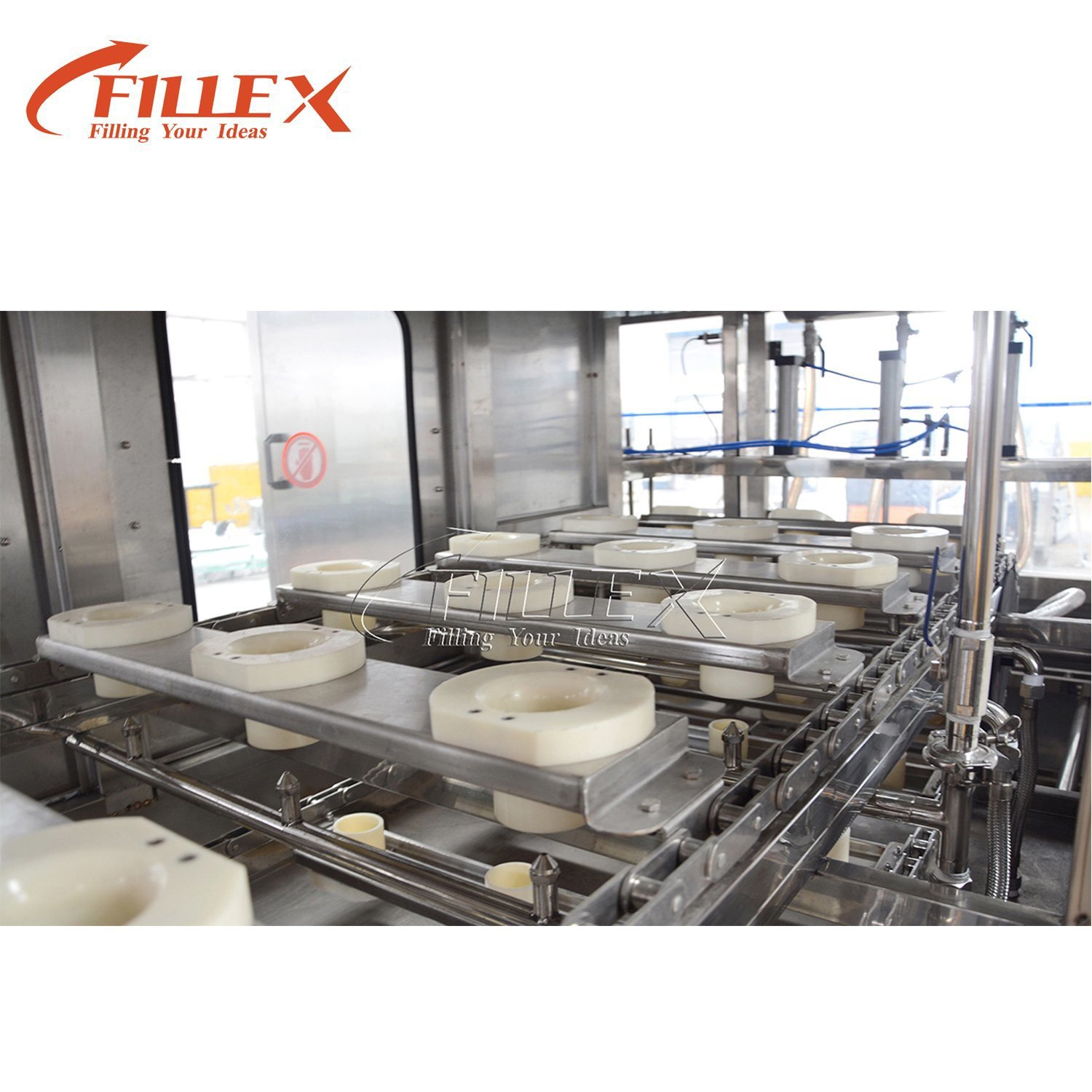

2. About washer

Nylon brushes, long life service life

Energy saving

The material of machine frame and body: all 304 Stainless Steel

No bottles no washing

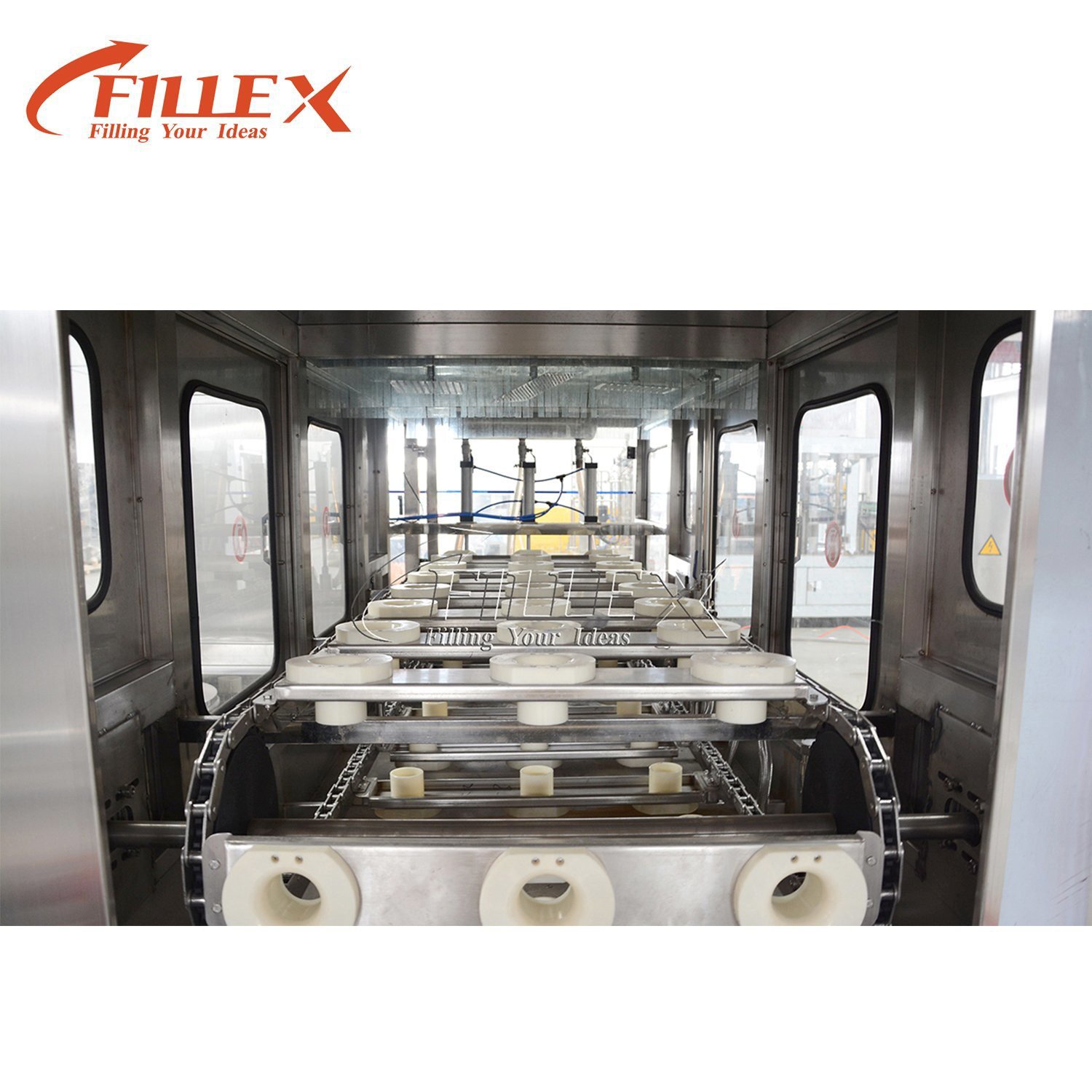

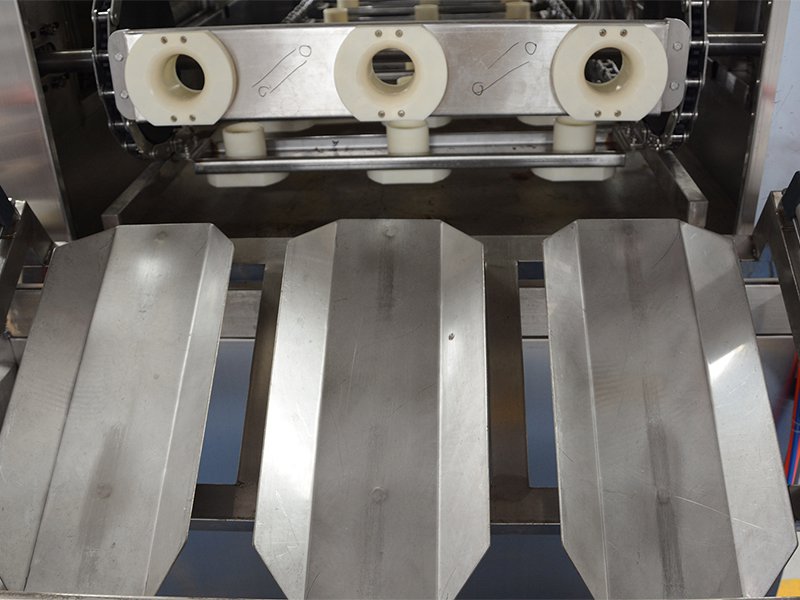

3. About the filler

Full-automatic PLC control, full-automatic working, filling level, filling time adjustable

Linear cylinder-pushed filling style, super high precision, ( when the capacity up to 800BPH, adopt the rotary filling system )

Food Class 304 or 316L stainless steel contact parts

No bottles no filling

Acutally it includes sterlizing, rinse filler capper, in order to make sure the recycling bottle is clean and aseptic, we used 4 stage flushing, hot alkaline water, detergent washing,recycling pure water, pure water washing, different capacitiy will be different sterlizing times, such as 300 bpph capacity, it is 2 times hot alkaline water sterilizing, 3 iimes detergent washing, 3 times recycling pure water washing and 2 times pure water washing.

Main technical standards:

1. Air move parts Yadeke

2. SIEMENSE AC products

3. Stainless steel conveyor: Stainless steel 304 or 316

4. Water proof frame in rotor axe

5. Brush speed control motor; 0.75kw

6. Dial wheel motor: 0.75kw

7. Washing pump: 0.37kw

8. Conveyor with motor: 0.27×3kw

9. Washing lotion with heating parts: 6kw

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years, can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high-quality machines with a 1-year guarantee and free spare parts for 1 year. Meanwhile, our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed on both sides.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.