- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

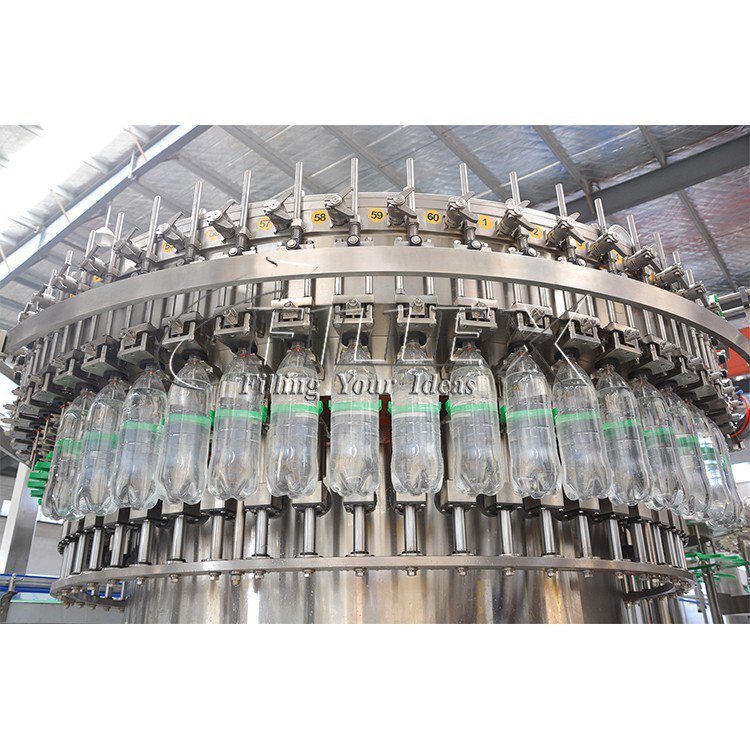

This equipment combines rinsing bottles, filling bottles and capping bottles together with PLC control. It is mainly used for plastic bottles with carbonated beverages and non-carbonated beverages.

1.Our RFCC series monobloc rinser filler capper style beer filling machine are adopted the negative pressure filling design, perfectly for bottling beer into glass bottles using metal crown caps

2. Adopts the negative pressure filling which we specifically design for CSD filling, it ensures minimal loss of CO2 from the product

3. The configuration of filler is advanced, pithy and rational and the driving and up-down transmission is located between the stainless steel working plat and the bracket and their waterproof is good, sanitary and credible and adjusting and maintaining are very easy.

4. The professional filling valves ensure the valves open and close flexibly because of using guide sheath. Adopting easy-fixed configuration, the valve is easy to cleaning promptly and has automatic cleaning function.

5. The filling operation is faster and more stable because the new type micro pressure filling system is adopted.

6. The electropneumatic filling valves are equipped with interchangeable level tubes to make the best precision filling, and the filling level for the bottle is adjust.

7. No bottle no filling, no bottle no capping

8. Bottles Protecting gripper to make sure the bottle non-crash during washing filling & capping steps

9. Available Models of our beer filling machine: (based on 500ml glass bottle) From 3000BPH to 8000BPH

| Model | 14-12-5 | 16-16-5 | 24-24-8 | 32-32-8 | 40-40-10 | 50-50-10 | 60-60-10 |

| Capacity | 3,000 | 5,000 | 8,000 | 12,000 | 15,000 | 18,000 | 20,000 |

| Suitable to Bottle Shape | Round and Square container Bottle Diameter : 50-120mm Bottle Height : 160-320mm | ||||||

| Drive Motor | 2.42 | 3.12 | 3.92 | 3.92 | 5.87 | 7.87 | 11.37 |

| Dimension | 2360*1770*2700 | 2760*2060*2700 | 2800*2230*2700 | 3550*2650*2700 | 4700*3320*2700 | 5900*4150*2700 | 5770*5290*2700 |

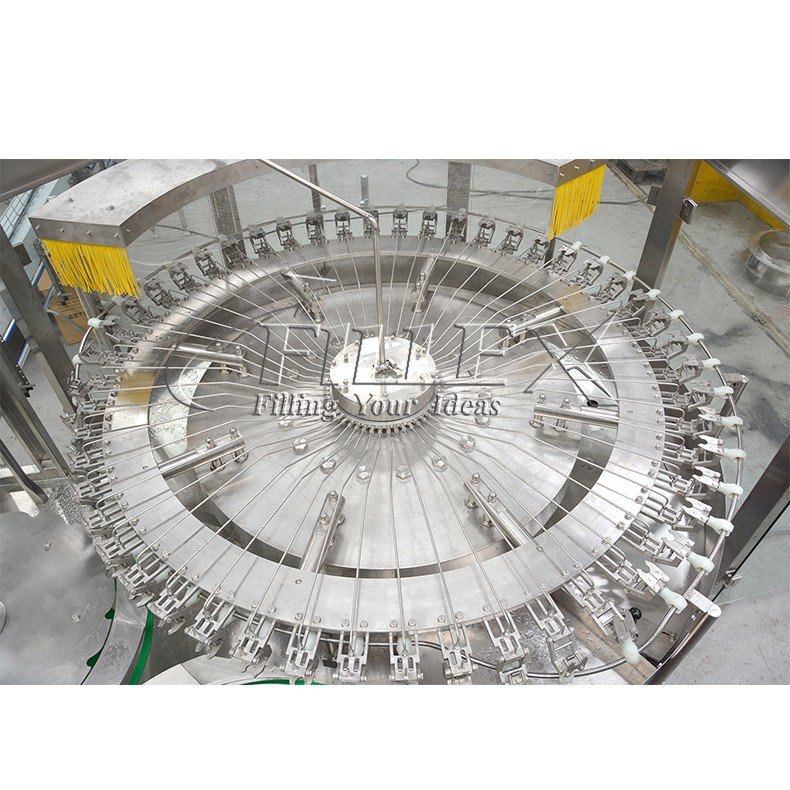

All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & clean

304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

304 stainless steel washing pumps

Spraying inject design, can completely washing the bottles.

High precision filling nozzle, PLC variable signal control, ensure high filling precision

Gravity filling, & filling smoothly & steadily

All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean

No bottle no filling

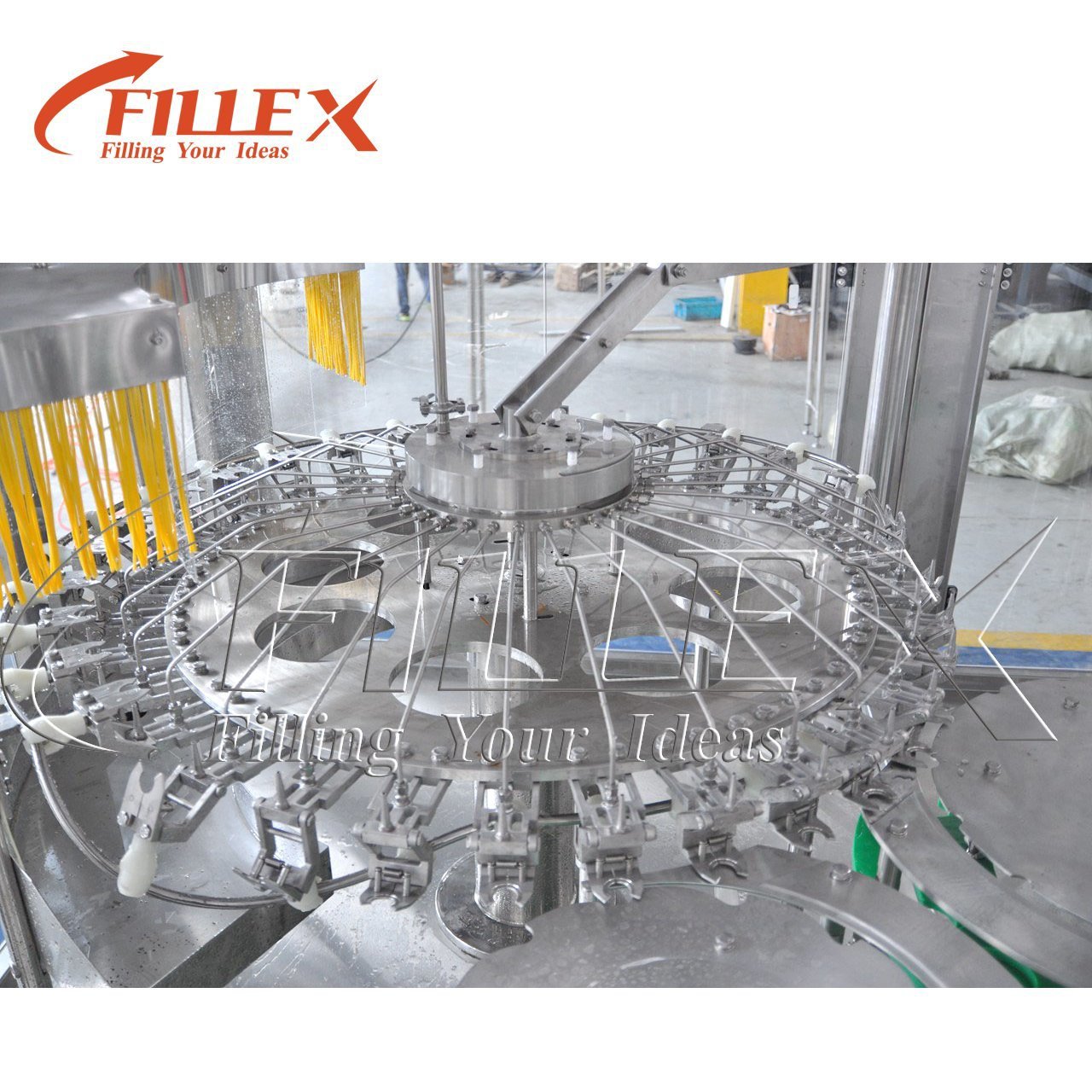

Place & capping system. Automatic caps arranging, feeding.

with burden discharge function, make sure minimum

bottle crash during capping

No bottle no capping and Automatic stop when lack of bottle

Automatic caps sorting, feeding

1. All parts contacting with beverages adopt top grade stainless steels whose surfaces are polished till smooth for easy rinsing. The sealing materials are EPDM rubber.

2. Adopt PLC as center control, make use of pressure transmitter and electromagnetism pneumatic valve to measure liquid level, keep balance of filling pressure to insure stable liquid level.

3. Adopt new type filling valves which are especially designed for plastic bottles. The returned air and the liquid in filling tank are insulated to insure cleanliness of the filled beverages.

4. Adopt advanced magnet clutches for capping with adjustable torsional moment to insure capping safely and reliably.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.